The super-abrasive tools which are made up of diamond and cubic BN are widely used in grinding all kinds of metal materials, stone, ceramic, optical glass and other hard materials. They can be used in lots of engineering areas, such as highway maintenance, geological mining, oil and gas drilling. The current used super-abrasive tools are usually manufactured by multilayer sintering or single plating process. The abrasive particles are embedded or enchased in the bonding layer, and a weak bonding strength is generally caused. In some cases under the heavy load, the weaker bonding strength could induce the shedding of the abrasive particles. Furthermore, the abrasive particles are randomly dispersed through multilayer sintering or single plating process, resulting in the lower exposing height and the less chip space. The above phenomenon can induce the adhering and blocking of debris during grinding, and thus decrease the manufacturing properties of tools and service life.

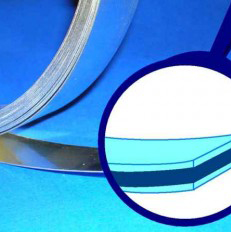

Due to the defects of abrasive tools made by multilayer sintering or single plating process, they are restrictively used in some cases, such as efficient grinding and high speed/ultrahigh speed grinding. In recent years, many authors tried to introduce the brazing technology to manufacture single layer super-hard abrasive tools. The bonding strength between the substrates and brazing alloy can be improved since the dissolution, wettability, diffusion and chemical combination occur at the interface among the abrasive particles, brazing alloy and substrates during high temperature brazing. The practices have proved that the brazing alloy showed good wettability and high coalescent strength to the substrates, without gaps or grooves existing. After brazing, the diamond abrasive particles keep integrated, no cracks occurring and show a high exposing height. Comparing with multilayer sintering or single plating process, the super-abrasive tools obtained through brazing show following advantages: (1) The abrasive materials, brazing alloy and substrates can be achieved through metallurgical chemical bonding, inducing strong bonding strength and long service life. (2) The exposing height of the abrasive particles was higher (up to 70%-80% of the height of abrasive particles), resulting in a large chip space and fully utilizing abrasive particles. (3) The brazing method could induce the lower grinding force, power consumption and grinding temperature. (4) The brazing method accords with current development trend of green manufacturing advocated, showing great significance in environment protection.

The super hard abrasive tools manufacturing through brazing are becoming a hot research due to its unique superiority.